晶圓基板,glass carrier 封裝晶圓, 與制程載具SOI wafer 等客制化解決方案.

4 Inch 單拋單氧 wafer 10 PCS

Diameter: 100 mm

Thickeness: 500 ± 25 um

Type/Dopant: N / Boron

Orientation: <100>

Resistivity: 35-40 ohm-cm

Single side polished oxidation : 2um

-------------------------------------------------

8 Inch Prime wafer 12 PCS

Diameter: 200 mm

Thickeness: 725+ / -25 um

Type/Dopant: P / Boron Orientation: <100>

Resistivity: 1以下 ohm-cm

Single side polished

-------------------------------------------------

4 Inch 單拋單氧 wafer 10 PCS

Diameter: 100 mm

Thickeness: 500 ± 25 um

Type/Dopant: N / Boron

Orientation: <100>

Resistivity: 35-40 ohm-cm

Single side polished oxidation : 2um

Silicon wafer

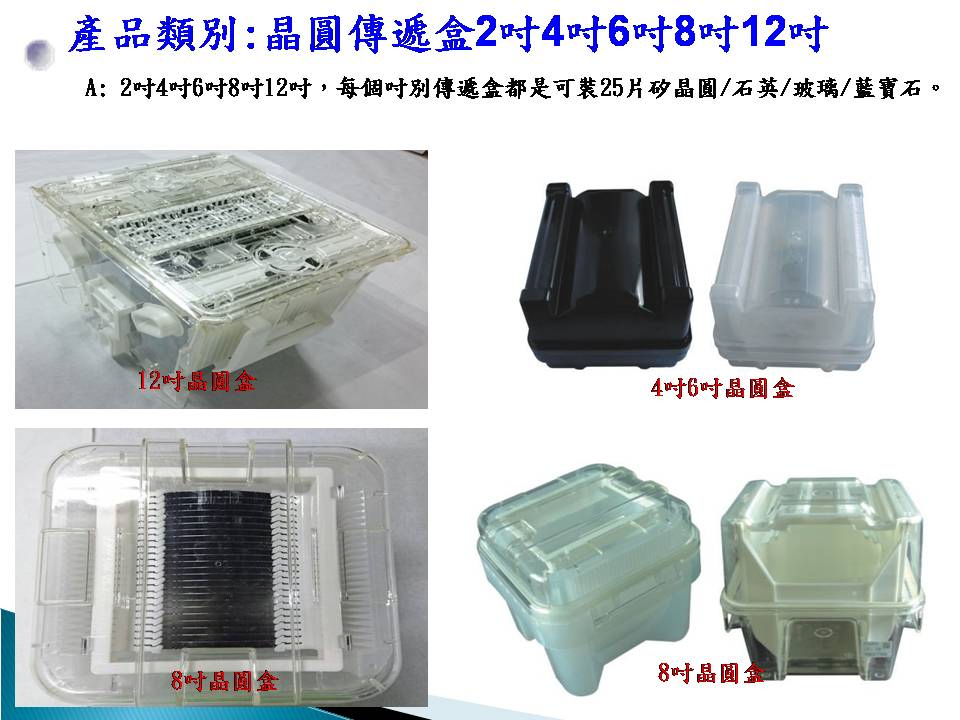

2”4”6”8”12”

Diameter

50.8mm

100mm

150mm

200mm

300mm

Type

P-type or N-type

Dopant

Boron/Arsenic/Phosphorus/Antimony

Orientation

<100>,<110>,<111>

Resistivity

0.0001 ohm-cm ~30K ohm-cm

SOI (Silicon on insulation) wafer

Diameter

3"~8"

Handle Layer Specification

Thickness

250-800μm

Type P or N

Dopant Boron, Sb or Phos. As.

Resistivity 0.001~>1,000Ω-cm

Growth Method CZ or FZ

Orientation<100>,<110>,<111>

Backside finish

Lapped/Etched; Polished

Buried Oxide Specification

Oxide grown on

Handle, Device or Both

BOX thickness0.2-5μm

Device Layer Specification

Thickness2-300μm

Type P or N

Dopant Boron, Sb or Phos. As.

Resistivity 0.001~>1,000Ω-cm

Growth Method CZ or FZ

Orientation <100>,<110>,<111>

Sapphire wafer2”4”6”

Diameter50.8mm100mm150mm

Thicknessstandard

OrientationC, A, R

Warp≦25μm

Bow≦25μm

TTV≦25μm

Front Surface

EPI polished(less than 5A)

Back SurfaceFine grind or polished

Glass / QuartSpecification

Glass Soda Lime/ Borofloat / Eagle XG / Others

Quartz Fused Silica, Quartz Crystal

Size2”~8”, Other shapes and sizes also available

Thickness0.5~1.8 mm, Made-to-order

Surface finish one side or two sides polished

Flatas SEMI. Standard

TTV<= 20 μm

Surface roughness

Ra <= 15 A

LiTaO3 / LiNbO3 Wafer

Black-LT and Black-LN

Specification of Bulk resistivity, Bulk conductivity

Black-LT

Standard Black

Super Black

Bulk Resistivity(Ω-cm)

0.9E+11~9.9E+11

1.0E+11~9.9E+10

Bulk Conductivity(ΩE-1-cmE-1)

1.11E-11~1.11E-12

1.0E-10~1.11E-11

Black-LN

Standard Black

Bulk Resistivity(Ω-cm)

1.0E+10~9.9E+10

Bulk Conductivity(ΩE-1-cmE-1)

1.11E-11~1.11E-12

Typical Specifications

Black-LT wafers

Orientation Diameter(mm) Thickness(mm) Surface finish

(+)plane (-)plane

36 Y-cut

38.7 Y-cut

42 Y-cut

48 Y-cut

X-112 Y-cut 76.2

100.0

0.25

0.35

0.50

Mirror

Polished

Black-LN wafers

Orientation Diameter(mm) Thickness(mm) Surface finish

(+)plane (-)plane

Y-Zcut

41 Y-cut

64 Y-cut

127.86 Y-cut 76.2

100.0

0.25

0.35

0.50 Mirror

Polished

EPI Wafer (Silicon Epitaxial Wafer) / SiC Wafer / GaAs Wafer / InP Wafer / Others

Glass, 玻璃 (Glass), 石英 (Quartz), 矽 (Silicon), 與特殊材料

矽晶圓 Silicon wafer

SOI wafer, CZ & FZ, P & N type, 100 & 111, Low & High resistance, Prime & Test grade.

石英 Quartz

熔融石英 (Fused Silica), 熔凝石英 (Fused Quartz), 紅外線石英 (Low OH).

硼矽酸玻璃 Borosilicate glass

Borofloat 33, Pyrex 7740, D263Teco.

無堿玻璃 Alkaline-Free glass

EXG, AF32, ABC, AN100

鈉鈣玻璃Sodalime glass

3C產品用的電子玻璃, 超白玻璃 B270.

強化玻璃 Toughening glass

Gorilla, Dragontrail.

濾光片Optical filters

UV filter, VIS filter, NIR, SWIR, LWIR filters, BK7

其他 Others

Sapphire (Al2O3), ALN, Ceramics, Diamond wafer, GaN, GaAs, Germanium, Graphene, LiTaO3, LiNbO3, SiC, ZrO2, etc.

晶圓基板,glass carrier 封裝晶圓, 與制程載具

直徑: Dia. 100, 150, 200, 與 300 mm.

表面粗糙度 (Ra):< 0.5 nm (MDF) 或 < 1.5nm (Standard).

拋光等級: 雙面拋光, 單面拋光, 雙面霧化, 單面霧化.

Roun圓形, 方形, 異形, 3D-IC的TSV & TGV interposer, Carrier wafer, GOS (Glass on Silicon), SOG (Silicon on Glass), QOS (Quartz on Silicon), SOQ (Silicon on Quartz), Prime & Test grade Silicon wafer, SOI wafer 等客制化解決方案.

按照SEMI Standard 或是JEITA 加工.

厚度:50μm 到 3000μm.

TTV:< 3 μm.

光學金屬鍍膜光學刻蝕設計

鍍膜: NWIR, LWIR, UV, AR, Cr, Au, Ag, Ti, Cu, Al, Sn等鍍膜可滿足特殊光學需求,

Low Defect 雙面AR鍍膜穿透率 > 99%.

雷射鑽孔切割加工 (In-Between Laser Processing)

化學強化玻璃, 無堿玻璃, 陶瓷, 藍寶石, 氮化鋁, 石英等透明硬脆材料.

穿孔,盲孔,開槽,預切,畫線,切斷.

適合複合材料切割 (玻璃+矽或陶瓷).

可加工超薄材料如厚度50um

90度斷面, 具遮光效果, 可用於玻璃導光板.

切割斷面崩邊 < 10um.

切割道寬度10um,透過縮小切割道可增加材料使用面積.

雷射直接鍵和硼矽酸玻璃, 無堿玻璃, 透明陶瓷, 藍寶石, 石英等同種透明硬脆材料.

高溫高速雷射直接焊接1500mm/s.

直接在材料交界中間燒結, 不需使用膠材, 玻璃粉, 或金屬.

可達到真空氣密封裝, 耐高溫與高壓.

鍵和通道的寬度為30~50um.

不傷材料, 快速鍵和時溫度集中於切割道, 封裝的材料溫度維持室溫.

TGV 填金鍍金 & TSV 絕緣

晶圓尺寸 4吋, 6吋, 8吋, 與12吋.

可應用於半導體(SEMI)與微機電 (MEMS) 3D interposer 制程.

製作低膨脹係數玻璃底材的TGV wafer.

厚度100um, 孔徑最小可達30um.

玻璃材料可使用客戶指定的材料, 選用膨脹係數的材料.

可先製作通孔, 表面鍍金或填充各種導電金屬, 的TGV wafer, 然後與矽晶圓鍵和.

TSV 做好Si導通電極後, 邊緣做SiO2絕緣.

UVA, UVC, UHB LED, OLED 封裝蓋板

材料白玻璃或石英

指紋辨識蓋板 & 封裝底部透明腔體加工

使用強化玻璃, D263, 藍寶石, 石英等材料.

用於指紋辨識Home 鍵封裝蓋板.

搭配光學或是金屬鍍膜.

可提供不同切割形狀, 如圓形或橢圓形.

托板車,油壓車,油壓板車,油壓拖板車,窄版托板車,昇降台車,升降平台車,升降台車,手動油壓車

企業名片

- 公司名稱:銳隆光電有限公司

- 連絡電話:037-******

- 電子郵件:ke*a*****@gmail.com

- 詢價官網:https://100192.web66.com.tw

歷史詢價

-

王*姐想要尋價一些五金工具02-24 17:48

-

蕭*有轉印過茄芷相関顏色?02-24 17:48

-

陳*生公司有做大陸到美國的物流嗎02-24 17:48

-

林*璇請問液體化學處理劑可否寄送到大陸02-24 17:32

-

陳*生想詢問安全帽價格 勞檢帽02-24 17:27

-

葉*生檢具報價 (需要信箱)02-24 17:23

-

楊*生工程配管配電工程、設備安裝、廠建工程02-24 17:11

-

顏*翎需要破布*3袋(30公斤)02-24 16:57

-

陳*生UPS SNMP Card02-24 16:55

-

蘇*姐想詢問是否有目錄可以供參考02-24 16:55

-

廖*姐豪華三排椅詢價 有此需求02-24 16:53

-

林*姐饗食天堂平日晚餐券 以下協助02-24 16:51

-

金*姐防水防曬防風帆布02-24 16:43

-

詹*穎褚式日常生活功能評估表第四版02-24 16:42

-

劉*生詢問 兒童雨鞋庫存品02-24 16:39

-

林*姐陳列道具搬運 第一趟02-24 16:10

-

吳*姐鋁製梯型 電纜架02-24 15:59

-

邱*生回收二手塑膠棧板02-24 15:54

-

黃*姐您好,想詢問報價02-24 15:52

-

王*姐詢問琉璃獎座單價02-24 15:27