1. Provision of 4% impedance

|

|

|

|

1. Provision of 4% impedance

2. Reduction of mains harmonics 3. Reduction of commutation notches 4. Protection of motor drive electronics 5. Limitation of inrush currents 6. Improvement of true power factor |

|

|

|

|

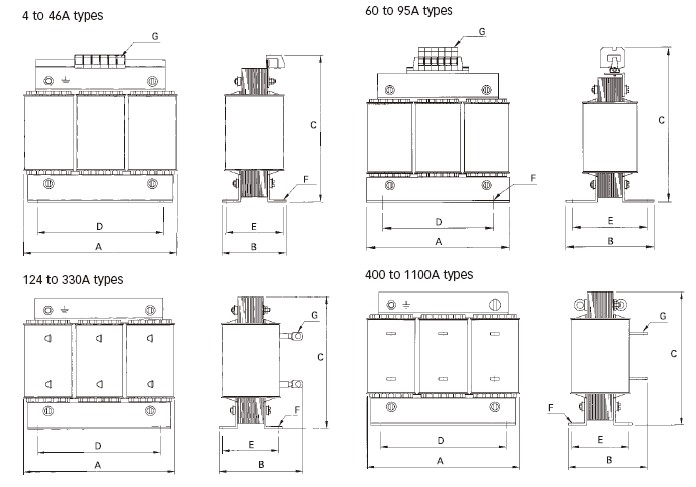

| Type: | RWK212 |

| Maximum continuous operating voltage: | 3x500/288VAC |

| Operating frequency: | 50 to 60Hz |

| Rated currents: | 4 to 1100A @40°C |

| Impedance (uk): | 4% @ 400VAC, 50Hz & rated current |

| Typical harmonics reduction: | See table on next page |

| High potential test voltage: |

P –> E 3000VAC for 3 sec P –> P 3000VAC for 3 sec |

| Protection category: | IP00 (KL types according to VBG4 |

|

Overload capability: |

2x rated current at switch on for 30 seconds 1.5x rated current for 1 minute, once per hour |

| Temperature range (operation and storage): | -25°C to +100°C (25/100/21) |

| Insulation class: |

T40/B (130°C )-> RWK 212: ≤95A

T40/B (155°C )-> RWK 212: ≥95A |

| Flammability corresponding to: | UL94V-2 or better |

| Design corresponding to: | EN 6155E-2-20 (VDE 0570-2-20) |

|

MTBF @40°C/400V (Mil-HB-217F): |

>200,000 hours |

|

|

|

|

|

|

|

|

|

|

1. Reduction of drive output voltage dv/dt 2. Reduction of motor temperature 3. Increase of motor service life 4. Compact and economic open frame design 5. Standard catalog reactors up to 1100A 6. UL rated materials used |

|

|

|

|

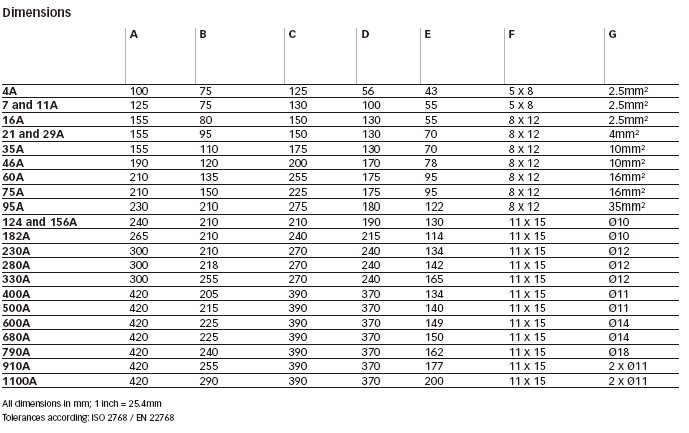

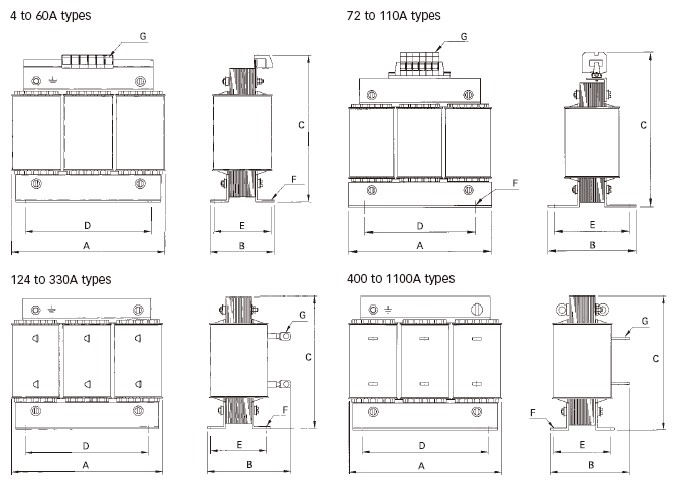

| Type: | RWK305 |

| Maximum continuous operating voltage: | 3x500/288VAC |

| Motor frequency: | 60Hz max. |

| Switching frequency: | 2 to 16kHz |

| Rated currents: | 4 to 1100A @40°C |

| Motor cable length: | 30m max. @ 16kHz (derating curve next page) |

| Impedance (uk): | 0.8% @ 400VAC, 50Hz & rated current |

| Typical harmonics reduction: | ≥ factor 5 |

| High potential test voltage: |

P –> E 3000VAC for 3 sec P –> P 3000VAC for 3 sec |

| Protection category: | IP00 (KL types according to VBG4) |

|

Overload capability: |

2x rated current at switch on for 30 seconds 1.5x rated current for 1 minute, once per hour |

| Temperature range (operation and storage): | -25°C to +100°C (25/100/21) |

| Insulation class: |

T40/B (130°C )-> RWK 305: ≤110A T40/B (155°C )-> RWK 305: ≥110A |

| Flammability corresponding to: | UL94V-2 or better |

| Design corresponding to: | EN 61558E-2-20 (VDE 0570-2-20) |

|

MTBF @40°C/400V (Mil-HB-217F): |

>200,000 hours |

|

|

|

|

|

|

空調維修:檢查空調冷卻系統的運作狀況,清潔和更換空調濾網,檢查冷媒壓力和補充

企業名片

- 公司名稱:力通自動化科技有限公司

- 連絡電話:07-3******

- 電子郵件:li***n@ffuba.com

- 詢價官網:https://ffuba.web66.com.tw

歷史詢價

-

王*姐想要尋價一些五金工具02-24 17:48

-

蕭*有轉印過茄芷相関顏色?02-24 17:48

-

陳*生公司有做大陸到美國的物流嗎02-24 17:48

-

林*璇請問液體化學處理劑可否寄送到大陸02-24 17:32

-

陳*生想詢問安全帽價格 勞檢帽02-24 17:27

-

葉*生檢具報價 (需要信箱)02-24 17:23

-

楊*生工程配管配電工程、設備安裝、廠建工程02-24 17:11

-

顏*翎需要破布*3袋(30公斤)02-24 16:57

-

陳*生UPS SNMP Card02-24 16:55

-

蘇*姐想詢問是否有目錄可以供參考02-24 16:55

-

廖*姐豪華三排椅詢價 有此需求02-24 16:53

-

林*姐饗食天堂平日晚餐券 以下協助02-24 16:51

-

金*姐防水防曬防風帆布02-24 16:43

-

詹*穎褚式日常生活功能評估表第四版02-24 16:42

-

劉*生詢問 兒童雨鞋庫存品02-24 16:39

-

林*姐陳列道具搬運 第一趟02-24 16:10

-

吳*姐鋁製梯型 電纜架02-24 15:59

-

邱*生回收二手塑膠棧板02-24 15:54

-

黃*姐您好,想詢問報價02-24 15:52

-

王*姐詢問琉璃獎座單價02-24 15:27